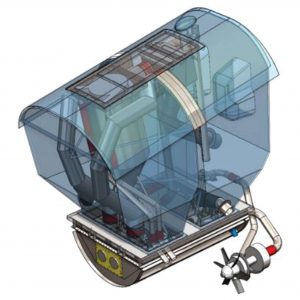

FireIce® Onboard Injection System

FireIce® Fixed Tanker Base

FireIce® Portable Tanker Base

Description

GelTech Solutions® owns and operates FireIce® mobile retardant base (MRB) equipment in a variety of configurations to meet the needs of wildland firefighting agencies worldwide. This equipment is a fully operated “Mobile Mixing Plant” for delivery of FireIce® to helicopters, single engine air tankers (SEAT), large airtankers (LAT), and very large airtankers (VLAT). This equipment is available for contract as a seasonal, call-when-needed (CWN), and emergency-ordered resource.

The FireIce® MRB equipment can be used for delivery with Multi-Engine and Single Engine Airtankers, Helicopters, and Ground Units at various locations. FireIce® personnel typically will perform the following activities: activation, mixing, loading, relocation, and/or deactivation. The requesting agency can also opt to self-operate the equipment. The MRB equipment can be ordered in any al-la-carte in the configuration desired by local, state, and federal agencies. The requesting agency may include orders for all additional equipment during initial order or order additional supplies such as Helicopter support, additional loading pits or additional mobile mix plants in a variety of configurations to additional locations.

Key Features of the FireIce® MRB Equipment:

- Ability to load mixed FireIce® into an aircraft 3” Camlock loading port at a rate of 300 gallons per minute for SEAT’s, 400 gallons per minute for multi-engine tankers, 600 Gallons per minute for Helicopters dip tanks.

- Capable of mixing FireIce® at a rate of 100,000 gallons over a 12-hour period.

- Capable of providing FireIce® to two SEAT loading pits at least 250’ apart simultaneously if ordered in that configuration.

- The mixing equipment will be able to draft and/or pump all required water from a non-pressurized source, a distance of 600 feet, in quantities sufficient to meet the mixing and loading requirements stated above.

When contracted, the equipment will come with at least (3) operators who will operate all equipment. Personnel will engage in the following operational activities:

- Set-up and mobilization of equipment

- Mixing FireIce®, including quality control

- Loading dip tanks and / or airtanker

- Relocation of equipment

- Demobilization of equipment

Specifications

Specifications

| (1) 3,500 gallon water tender – WT-271 (330 HP, 750 GPM PTO Pump) |

| (1) Ultra High Volume 4” Eductor capable of mixing 350 GPM (minimum) |

| (1) 32 foot 40,000 lb. capacity Zieman Trailer |

| (3) 4” trash pumps capable of 500 GPM |

| (3) Approved helicopter rigid steel dip tanks (15,000 Gallon total storage) Capacities: 6,000; 5,100; 4,200 gallons |

| (1) Telehandler forklift |

| 500 ft+ of 3” hose; 500 ft+ of 4” hose |

| (2) load hose / nozzle assemblies |

| Hose skates |

| Other miscellaneous fittings, adaptors, etc. |

| Additional vehicles available (pickup trucks, forklifts, etc.) for additional cost |

Reference Documents

Reference Documents

Product Sales Information

Scientific Testing & Data Information

Purchase

Purchase

orders@geltechsolutions.com | 800-924-4874

Media

Media

Categories: Equipment, Foam, Gels, Wildland & Timber